Big ganda

{Ketebalan: 120 180 30um 70um

{Lebar standar: 1290mm, urang tiasa motong salaku perayaan ukuran

{ID: 76 mm, 152 mm

{Panjang: ngaropéa

{Sampel tiasa asupkeun; Waktu mingpin: 7days

{Waktu pangiriman: 15-20days

{Rincian bungkusan: Ékspor kotak kayu

{Istilah: FOB, CIF.

{Item pamayaran: 50% T / T Deposit, kasaimbangan mayar sateuacan pengiriman.

{Peralatan Kinampuan Tinggi Tinggi ngalakukeun ngolah lega tina foil tambaga.

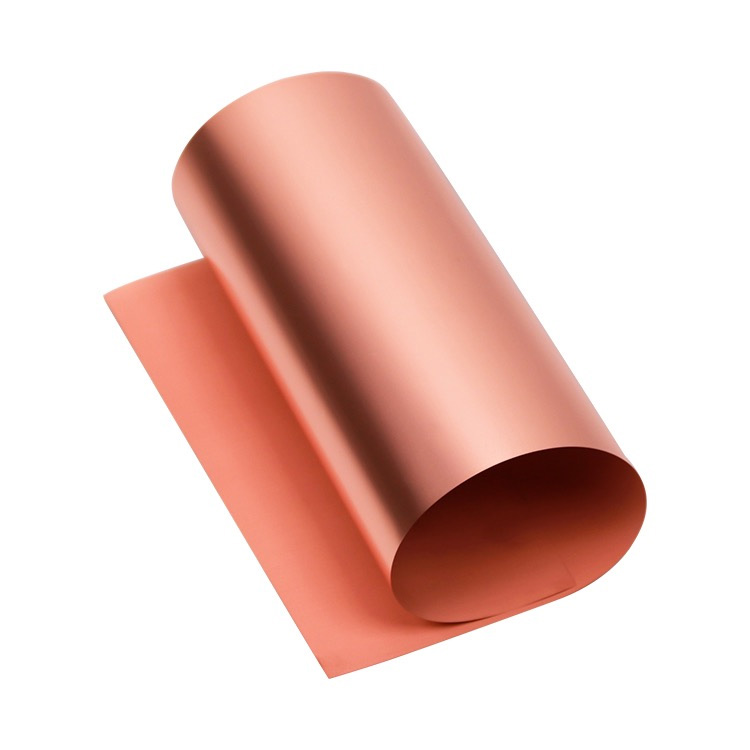

{Sisi ganda dina foil tambaga

{Kalayan kakuatan beungkeutan anu luhur

{Lambalan mulia langsung

{Etchability alus

{Foil anu dirawat nyaéta pink

{Multilayer nyitak dewan sirkuit

{HDI (Intronnik Tinggi) kanggo PCB

| Klasifikasi | Satuan | Sarat | Métode uji | ||||||

| Designation foil |

| T | H | 1 | 2 | IPC-4562 | |||

| Ketebangan nominal | um | 12 | 18 | 35 | 70 | IPC-4562 | |||

| Beurat area | g / m² | 107±5 | 153± 7 | 285 ± 10 | 585± 20 | IPC-Tm-650 2.2.12 | |||

| Kasadi | % | ≥99.8 | Ipc-tm-650 2.3.15 | ||||||

| Rochugness | Sisi ngagurilap (ra) | um | Eusian3.0 | Ipc-tm-650 2.2.17 | |||||

| Sisi Matte (RZ) | um | Eusian6 | Eusian8 | Eusian10 | Eusian15 | ||||

| Kakuatan regangan | Rt (23 ° C) | MPa | ≥207 | ≥207 | ≥276 | ≥276 | IPC-Tm-650 2.4.18 | ||

| H.T. (180° C) | ≥103 | ≥103 | ≥138 | ≥138 | |||||

| Elongasi | Rt (23 ° C) | % | ≥2 | ≥2 | ≥3 | ≥3 | IPC-Tm-650 2.4.18 | ||

| H.T. (180° C) | ≥2 | ≥2 | ≥2 | ≥3 | |||||

| Tahan | ΩG /m² | Eusian0.170 | Eusian0.166 | Eusian0,162 | Eusian0,162 | Ipc-tm-650 2.5.14 | |||

| Kakuatan kulit (fr-4) | S sisi | N / mm | ≥0,9 | ≥0,9 | ≥1.4 | ≥1.4 | Ipc-tm-650 2.4,8 | ||

| Lbs / di | ≥5.1 | ≥6,3 | ≥8.0 | ≥8.0 | |||||

| M sisi | N / mm | ≥0,9 | ≥1.1 | ≥1.4 | ≥2.0 | ||||

| Lbs / di | ≥5.1 | ≥6,3 | ≥8.0 | ≥11.4 | |||||

| Pinoles & Purifa | Jumlahs | No | Ipc-tm-650 2.1.2 | ||||||

| Anti-tambonomna | Rt (23 ° C) | Poé | 180 | / | |||||

| H.T. (Mimiti 200° C) | Menit | 40 | / | ||||||

Lebar standar, 1295 (± 1 1 1) mm, bauns lebar: 200-134mm. Mungkin numutkeun paménta nasabah.

Gambar Foil Cocper